Contact us!

Switchboard number:086-0518-85380151

15312113188 Manager Zhu

|

|

|

|

|

|

|

What is crane tube? (Brief introduction to crane tube) |

Usage: for transferring liquid products between trestle and car or train tank cars.

Loading method: A. Tank car top open loading

B. Tank car top closed loading

C. Tank car bottom loading

Balance method: counterweight balance, spring balance

Drive method: manual, pneumatic

Pipe material: carbon steel, stainless steel, carbon steel – polytetrafluoroethylene liner

Sealing material: nitrile rubber, fluorine rubber, polytetrafluoroethylene

Revolving joint: the sealing face is subject to build-up welding with stainless steel

Specification: the standard design is DN50, DN80 and DN100. Other specification shall be designed and manufactured according to the user’s requirements.

Design pressure: PN0.6~PN6.0MPa

Design temperature: -196℃~200℃

Optional accessories: automatic vacuum relief valve, manual vacuum relief valve, outer arm lock, inner arm reset lock, oil receiving box, globe valve, liquid level alarm system, heat tracing system.

Selection principle: 1. select the model according to the brief diagram (see the selection example for selection method).

2. Fill in the design conditions according to the crane tube design condition table.

3. Select associated accessories.

4. Select proper vertical pipe type and length C (describe whether to conduct subsurface loading).

|

|

|

|

Land Liquid Loading Arm |

The land liquid loading arm (loading arm) is composed of rotating joints with good rotating flexibility and sealing performance and pipes, and it is a device used between the tank car and the trestle storage and transportation lines for the transmission of liquid medium.

The key parts, i.e. rotating joints, are processed by precision numerically-controlled machine tools and they have the supporting structure with build-in double raceway, which rotates flexibly and is light and reliable. The outer ring adopts alloy steel while the inner ring adopts stainless steel or PTFE liner so as to ensure that the device can safely and reliably apply to high-temperature, low-temperature or highly-corrosive medium.

The sealing ring adopts reinforced PTFE, and the lining stainless steel elastic supporting ring and sealing are polished, having excellent self-lubrication property and corrosion resistance.

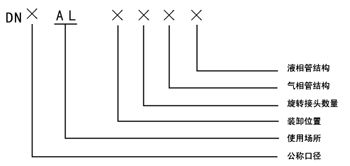

Instructions for model Instructions for model

- ?Nominal diameter: Based on the diameter of the liquid-phase pipe of loading arm.

- ?Code of using place: Letters AL means the loading and unloading work for train or truck tank.

- ?Code of loading location: 1-Top loading 2-Bottom loading

- ?Code of number of rotating joints: Calculating the rotating joints of liquid-phase pipe 4-4 rotating joints 5-5 rotating joints

- ?Code of structure of gas-phase pipe: 0-No gas-phase pipe 1-Up-connected 2-Down-connected 3-Up-turning 4- Down-turning

- ?Code of structure of liquid-phase pipe: 1-Up-connected 2-Down-connected 3-Up-turning 4- Down-turning

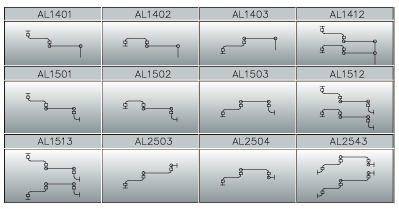

Main models and diagrams of their structures Main models and diagrams of their structures

Specifications / standards for design, manufacturing and acceptance Specifications / standards for design, manufacturing and acceptance

- HG/T21608-96

- H/QB1006-93

- GB12459-90

- GB 700

- GB 3077

- GB 8163

- JB755-85

- GB 308

- GB 3323-87

- DIN8563 T1

- DIN8563 T2

- DIN8563 T3

- GB985-88

- GB/T 8923-88

- GB/T 13384-92 |

Liquid Loading Arm

Liquid Loading Arm – Manufacturing Part

Steel Butt-Welding Seamless Pipe Fittings

Standard Specification for Carbon Structural Steel

Technical Requirements for Alloy Structure Steel

Seamless steel Tubes for Liquid Service

Technical Requirements for Forgings of Pressure Vessels

Rolling Bearings -Steel Balls

Methods for Radiographic Inspection and Classification of Radiographs for Fusion Welded Butt Joints in Steel

General Tolerances for Welded Constructions – Dimensions for Lengths and Angles

Quality Assurance during Welding, Requirements for Factories

General Tolerances for Welded Constructions -- Dimensions for Shapes and Positions

Basic Forms and Sizes of Weld Grooves for Gas Welding, Manual Arc Welding and Gas-shielded Arc Welding

Rust Grades and Preparation Grades of Steel Surfaces before Application of Paints and Related Products

General Specification for Packaging of Mechanical and Electrical Products |

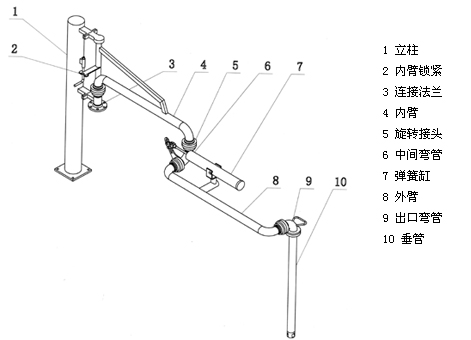

Composition of structure Composition of structure

Product features Product features

- The double-raceway rotating joints and the sealing rings having elastic clamp ensure the medium will not leak during loading;

- The spring cylinder balancer equipped with neutral equilibrium makes the loading arm to be operated in a convenient and labor-saving way;

- During the loading, it moves along with the tank within the normal moving range of tank;

- When the loading arm is recovered, it is locked in the direction in parallel with the travelling direction of tank, occupying small space;

- With rational structure, the smallest arm size can meet the most reasonable envelope scope.

Main parameters Main parameters

- Applicable medium: Various liquid and gaseous products

- Design temperature:-196℃-250℃

- Nominal diameter: DN50-DN150

|

- Design pressure: -0.08Mpa-6.0Mpa

- Pipe material: Carbon steel, stainless steel, liner pipe

- Work envelope scope

- Key point for ordering:

Please fill in the Loading Arm Design Data Sheet under the guidance of technicians of our company and provide related drawings.

|

|

|

(crane tube) land type fluid handling arm |

AL1401 AL1401

Using place: Open loading work at the top of a tank truck; the pipe joint is downward

Applicable medium: Crude oil, refined oil product, chemical medium

Working pressure: 0.6Mpa-2.5Mpa

Pipe material: 20#/304/316/ aluminum

|

|

AL1402 AL1402

Using place: Open loading work at the top of a tank truck; the pipe joint is downward

Applicable medium: Crude oil, refined oil product, chemical medium

Working pressure: 0.6Mpa-2.5Mpa

Pipe material: 20#/304/316/ aluminum

|

|

AL1403 AL1403

Using place: Open loading work at the top of a tank truck; the pipe joint is upward

Applicable medium: Crude oil, refined oil product, chemical medium

Working pressure: -0.08Mpa-2.5Mpa

Pipe material: 20#/304/316/ aluminum |

|

AL1412 AL1412

Using place: Open loading work at the top of a tank truck; the pipe joint is upward

Applicable medium: Volatile and toxicant chemical medium

Working pressure: 0.6Mpa-2.5Mpa

Pipe material: 20#/304/316 |

|

AL2503 AL2503

Using place: Closed loading work at the bottom of a train; the pipe joint is upward or sidewise

Applicable medium: Low-fluidity medium, like crude oil

Working pressure: -0.08Mpa/ self-flow

Pipe material: 20#/304 aluminum joint |

|

AL2504 AL2504

Using place: Closed loading work at the bottom of a train; the pipe joint is upward or sidewise

Applicable medium: Low-fluidity medium, like crude oil

Working pressure: -0.08Mpa/ self-flow

Pipe material: 20#/304 aluminum joint |

|

AL2543 AL2543

Using place: Closed loading work at the bottom of a truck; the pipe joint is sidewise

Applicable medium: Liquid gas, liquid chlorine, liquid ammonia, etc.

Working pressure: 1.0Mpa-4.0Mpa

Pipe material: 20#/304/316

| |

AL1512 AL1512

Using place: Closed loading work at the top of a train; the liquid-phase pipe joint is downward or sidewise

Applicable medium: Liquid gas, liquid chlorine, liquid ammonia, etc.

Working pressure: 0.6Mpa-2.5Mpa

Pipe material: 20#/304/316 |

|

AL14.3 hydraulic pump type AL14.3 hydraulic pump type

Using place: Open loading work at the top of a tank truck; the temperature is high and the medium is easy to volatilize

Applicable medium: Light oil

Working pressure: -0.08Mpa

Pipe material: 20#/304/ aluminum pump |

|

Heat-tracing type Heat-tracing type

Using place: Open loading work at the top of a tank truck; the medium has poor fluidity, and it shall be heated and kept warm

Applicable medium: Crude oil, residual oil, pitch, etc.

Working pressure: -0.08Mpa-2.5Mpa

|

|

Liner type Liner type

Using place: Open loading work at the top of a tank truck; the liquid-phase pipe joint is upward or downward

Applicable medium: Highly-corrosive medium like strong acid or strong alkali

Working pressure: -0.08Mpa-2.5Mpa

Applicable models: AL1401 AL1402 AL1403 |

|

Non-column type Non-column type

Using place: Various fluid loading environment; the installation site is narrow, not stopped or transformed

Applicable medium: Various liquid medium

Working pressure: -0.08Mpa--4.0Mpa

Pipe material: All types of loading arms mentioned above |

|

|

|

Bottom loading arm

This loading arm is a new product with proprietary intellectual property rights developed by our company based on the overseas and domestic market in recent years, meeting the safety and environmental protection requirements, and it can replace like products abroad. |

|

|